Fire penetrations are an essential part of ensuring the safety and compliance of plumbing, HVAC, and electrical installations in high-rise and commercial projects. Choosing the right products and following specific steps is important for a successful and compliant outcome.

Here are the 7 steps you need to know, along with accompanying questions to guide you in choosing the right product and getting compliant:

Step 1: Identify the Element to be Penetrated

Exact details are needed. Determine whether it's a floor, wall, or ceiling penetration. Examples include a 150mm concrete slab, 100mm masonry wall, single-layer 13mm standard plasterboard wall, or a double-layer 13mm standard plasterboard wall with a 64mm stud on each side or 75mm Hebel, among others.

Question: What element are you penetrating, and what are its exact specifications?

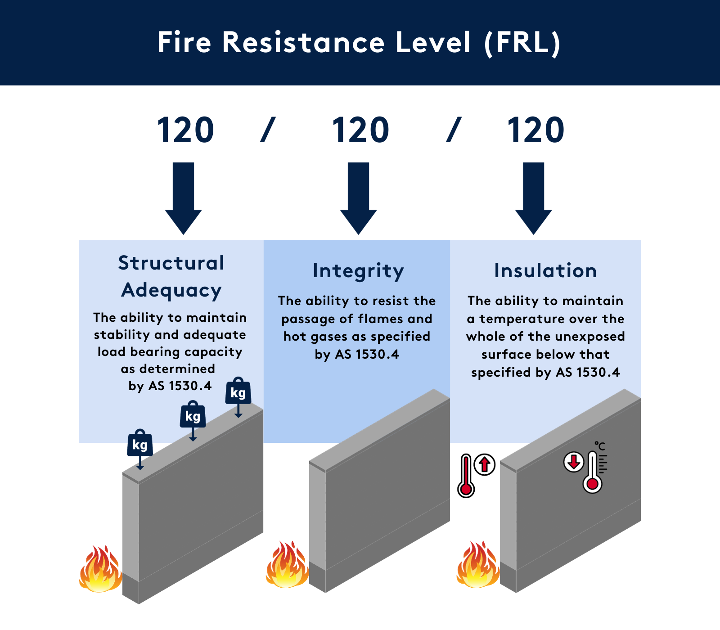

Step 2: Specify the Required Fire Resistant Level (FRL)

Understand the FRL needed for the element. A tested system with a higher FRL can be applied where a lower FRL is required on the same element. Ensure the FRL of the chosen system matches or exceeds the FRL of the element. FRL consists of three parts and looks similar to this: 120/120/120.

Question: What is the required Fire Resistant Level (FRL) for the element you are penetrating?

Step 3: Identify the Services Running Through the Penetration

Determine the type of services, which may include pipes, cables, pair coil, conduit, cable tray, ducting, etc.

Gather all necessary details, such as:

the wall thickness of pipes,

pressure grade,

manufacturer and more.

Question: What services are running through the penetration, and what are their specific details?

Step 4: Determine the Size and Space Required for Services

Specify the size and number of services and assess the space available. E.g. consider the diameter of pipes, the need for separation between services, and the maximum space available.

For cables, calculate the conductor area, number of cores, and bundle size. Additionally, we may need to work out specific details like the conductor area and number of cores, as shown in the example of 2.5mm² 3C + E, while also considering other factors.

Question: What is the size and space required for the services, and are there any specific considerations for installation?

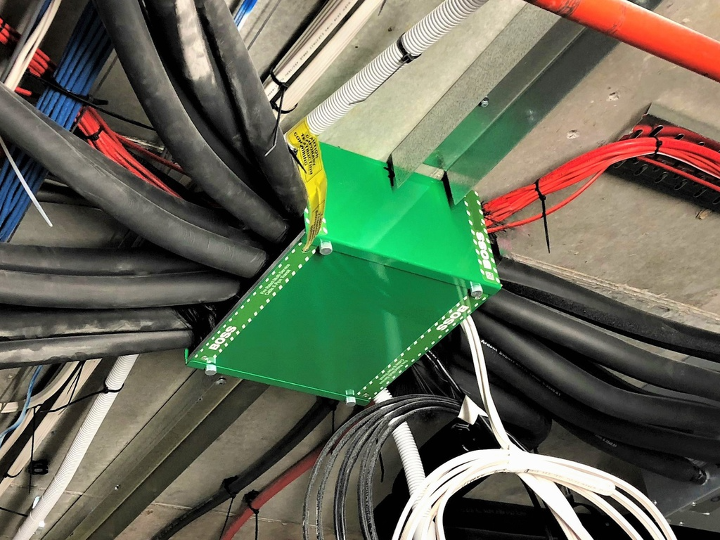

Step 5: Define the Core Hole or Penetration Size

For multiple services, assess if a Fire Box size could fit. Determine the dimensions or diameter of the hole drilled through the element, making sure proper clearance around the service meets the applicable test report.

Question: What is the core hole or penetration size required, and can a Fire Box size accommodate multiple services?

Step 6: Ensure Access to Test Reports

Collate all necessary test reports, emphasising the importance of actual reports over test certificates. Ensure that these reports are up-to-date and accurately reflect the fire-resistant capabilities of the chosen system.

Question: Do you have access to all the required test reports, and are they current?

Step 7: Record All Penetrations

Look at implementing a Fire Matrix System to track all penetrations throughout the project. This system helps maintain an organised record, ensuring that every penetration meets the necessary standards and compliance requirements.

Question: Have you implemented a Fire Matrix System to record and track all penetrations across the project?

By following these seven steps and answering the questions, your fire penetrations are done right the first time. Prioritising the selection of appropriate products and following a systematic approach not only simplifies the installation process, but also guarantees compliance with safety standards. Remember: Done Right. Done Once.